Smart Frame Benefits

OHS Friendly Design

- Eliminates the need for personnel to lift the conveyor belting in order to replace damaged idlers.

- Manual handling is reduced - Personnel only need the replacement idler, spanner, and extraction tool. No heavy jacking equipment and special spreader or lifting bars are necessary.

- Ideal where access is restricted, and on high belt tension areas.

- Elimination of reaching or lifting tasks inside the stringers.

- Awkward postures are avoided due to the relative ease of access to faulty idlers that are situated in difficult positions and locations.

Reduced Ongoing Maintenance Costs

- Suspect idlers can be replaced at the time of identification.

- Inspection time and planning time to manage the replacement of faulty idlers is greatly reduced. Thus, improving resource utilisation.

- Idlers can be accessed without the need to construct time consuming scaffolds, and eliminated is the hire of expensive boom lifts.

- A typical installation has up to 50% less idlers than conventional structure. Therefore, there is reduction in rolling stock volumes.

Increased Conveyor Belt Life

- Faster response to replace a suspect idler reduces the risk of belt damage such as wear from cover scuffing, belt rips and tears.

- Improved tracking of the belt is achieved by the standard fitment of tracking slots. This aids in preventing excessive edge wear.

- Reduced risk of idler-generated fire and subsequent belt damage.

- Flexibility in mounting and configurations

- Frames can be specified for floor mount, roof mount, stringer mount.

- Configurations available include a combination trough and return set, trough set only design, and a return set only.

- All configurations can be tailored to fit into an existing application.

In designing the Smart Frame™ Idler Structure, Cove applied sound engineering practices, and as a result have arrived at a design that not only eliminates the necessity to stop the production process to replace a suspect idler, but also significantly reduces the manual handling risk associated with replacing idlers in traditionally designed frames.

The Smart Frame™ is individually tailored to client mounting and idler configuration specifications. This versatile product is available in a wide variety of styles. Such as:

- Combined trough and return

- Trough only

- Return only

Options for mounting the structure include:

- Floor mounted

- Roof mounted

- Stringer mounted

The design also caters for single or dual return idler specifications and configurations.

The unique Smart Frame™ design facilitates hassle free retro-fitting to existing conveyor systems in addition to it being recognised as the obvious choice as the preferred standard for new conveyor systems.

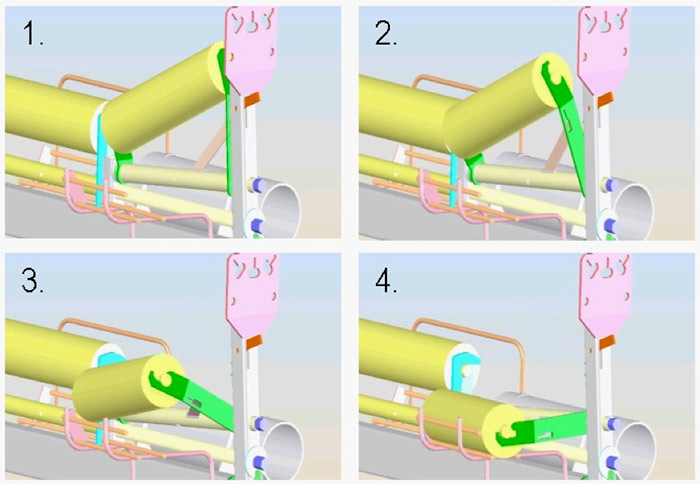

All idlers have a simple hand operated locking mechanism included as part of the design that firmly fixes them in the normal production position. A maintenance free pivoting shaft arrangement facilitates radial movement of the individual idler that is being replaced. This radial motion is achieved via a robust hexagonal spigot and a conventional spanner or socket tool.

The wing idler changing process (note: special tool is omitted from top blue pivot point for clarity)

All wing idlers are designed with an additional shaft mounting slot to aid in fine tuning of belt tracking. This minimises the potential for premature conveyor belt edge wear and damage to belt and structures.

In-situ replacement of the all idlers is made possible by incorporating a series of baskets to capture the idler as it is lowered away from the normal operating position. These baskets allow the idlers to be extracted and inserted onto the frame from the relative comfort and safety of the walkway, outside of and separated from the high risk nip points associated with all conveyors.

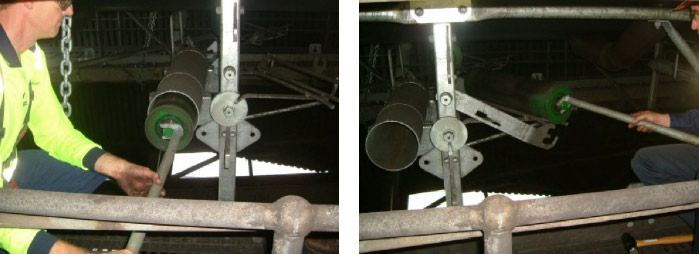

Demonstration of the Smart Frame™ idler changing process for the centre idler (left)

and wing idler (right) on a 6000 tph conveyor at a ship loading facility in NSW, Australia

A proprietary tool is supplied with each installation that enables the technician to retrieve the faulty idler and to position the replacement idler whilst maintaining a safe distance from the rotating components within the immediate maintenance and operational environment.

Consideration for compliance to the relevant Australian Standards is a key inclusion in any Smart Frame™ design. In particular, all installations progress through our risk assessment and auditing process for compliance to AS1755/AS4024 Conveyor Safety Standards.